Air Enthalpy Method Calorimeter

Test Chamber

- The chamber is made of Foam-core panel walls are superior to conventional walls in a number of ways.

- Foam-core panels combine a high level of insulation with speed and ease of construction.

- It resists high moisture levels do not significantly affect the R-value of foam-core panels.

- The solid foam core virtually eliminates air convection within the walls and thermal bridges through wood studs and insulation voids.

- The panels also reduce air infiltration that, with proper installation, make a tightly sealed chamber. The Chamber MUST be installed indoor .

Features

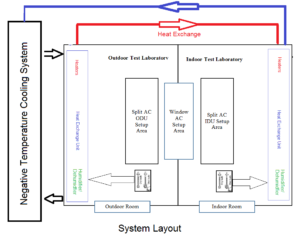

- Two Rooms one for indoor and the outdoor simulation .

- Internal Dimensions: 2.5m height X 4m width X 4mDepth each room

- Min Space required: ِ Approximate 3m height X 12 width X 5 depth.

- Out Door instillation capability: No

- Fire Alarm: Yes.

- Energy saving light: Yes.

- Automatic Door Locking: yes.

- Temperature control range (15 to 40) ±2 ° C

- Temperature Distribution inside the room: Less than 2 ° C /Meter.

- Temperature control stability: less than +/- 1 ° C.

- Relative humidity Control Range: (35: 90) ± 5%.

- Relative humidity Control Range Stability: +/-2%.

- Chamber manufactured from composite panel (sandwich panel)

- The design is such that it is possible to increase the capacity of the size of the room.

Air Handling System

- Ultra compact unit that can be integrated into the testing chambers.

- Advanced Temperature /Humidity control algorithm developed by our R&D team.

- Anti corrosion painting.

- Advanced ultrasonic humidifier.

- Smart Air circulating unit cooling unit minimize the compressor on time.

- Temperature range: 15 to 25 oC .for indoor side and 25 to 40 for out door side.

- Temperature accuracy: +/- 1 oC .

- Humidity range : 10% to 90%

- Humidity accuracy : +/- 5% ;

- Fan Speed: variable and automatically selected.

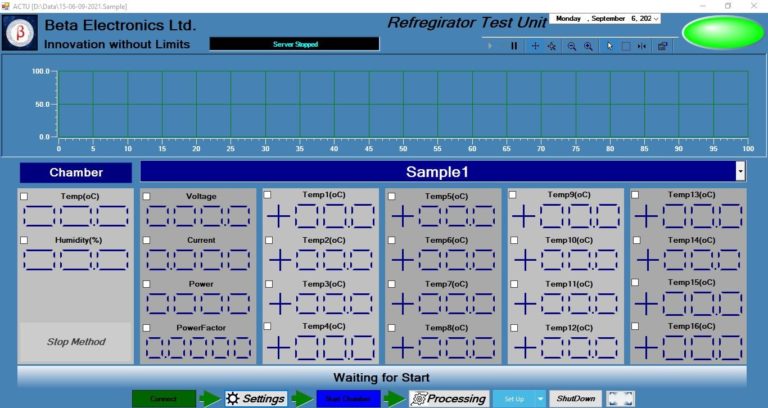

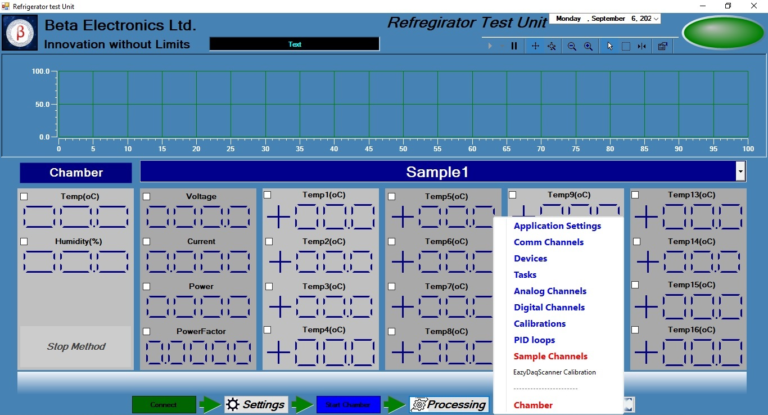

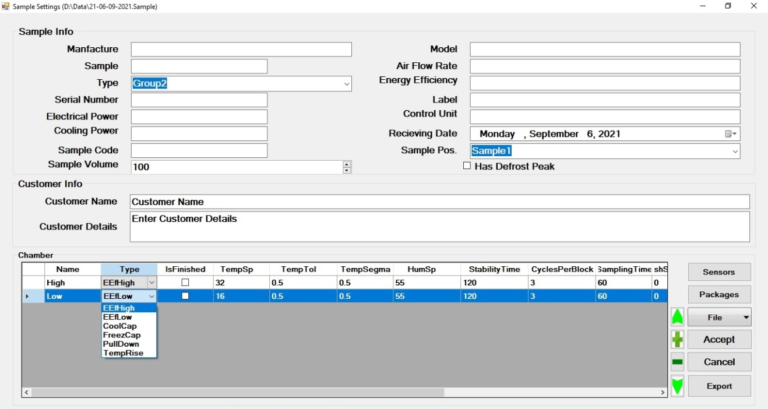

Data Acquisition System and Control Software

The data acquisition system is a solution for operating a test laboratory to measure the energy efficiency of Air Conditioners.

The modular system could upgrade the system easily with more input and output channels when the need arose. Data acquisition and control systems, installed in a control cabinet in the test laboratory, in the combination with the professional signal basic software .The thermocouple and the flow sensors will be connected directly to the devices without the need for any intermediate converters.

Data Acquisition System and Control Software Specification:

- The data acquisition system is a solution for operating a test laboratory to measure the Energy efficiency of Air Conditioners.

- The modular system could upgrade the system easily with more input and output channels when the needed.

- The control software has the possibility to test air conditioner unit.

- The system have a dual system automatic and manual with the following.

- The system will be supplied with a completely automated data acquisition and software systems.

- All connected transducer should be matched with the data acquisition .

- The software has advanced reporting system can export reports to different Microsoft Office.

- The software can monitor actionand events of all control processing(event logger).

- The application software will measure all pressure transducers and measure airflow.

- The application software will be capable of data entry and storing of the test results regarding to ISO 5151,ISO 13253 and ISO 16358

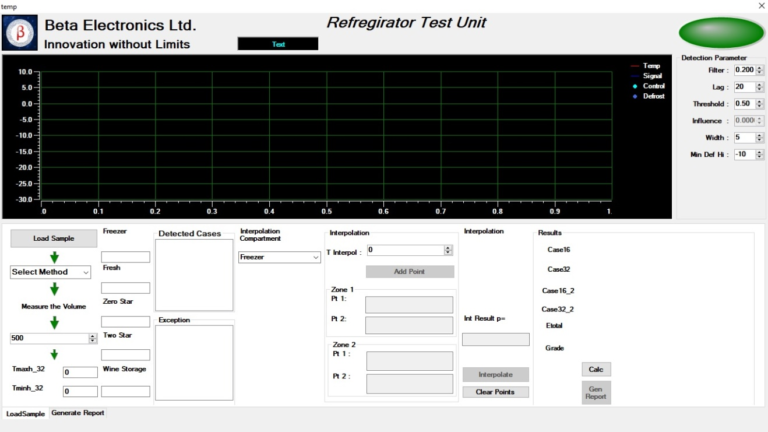

- The software will be detect and monitor steady state conditions

- The application software will be able to sense the abnormal condition, and discriminate the problem type and send alarm

- The application software should be able to calculate, analyze and store the measured data on running Mode , Also it should chart graph of the following data and measurement of the UUT :

- Date

- Power ,Current, voltage, frequency, and power factor profiles

- Dry bulb and Wet bulb temperature for indoor room

- Dry bulb and Wet bulb temperature for outdoor room

- Dry bulb and Wet bulb temperature for outdoor room and for air leaving the UUT

- Total energy consumption(KWH)

- Air flow rate for the UUT

- Cooling Capacity

- Energy Efficiency Ratio (EER)

Control Panel & DAQ

- Features

- Fan less industrial computer for maintenance free 24/7 operation.

- System events log system for trouble shouting.

- Automatic resume of the current job.

- User protection password.

- Automatic Shut Down option.

- Advanced watch Dog timer.

- Software control chamber light.

- PID Auto tune

- Advanced calibration

System Objective

- Maximum cooling test

- Minimum cooling test

- Freeze-up drip test

- Condensate control and enclosure sweat test

- Maximum heating test

- Minimum heating test

- Automatic defrost test

- Energy efficiency test